Shower enclosures must withstand demanding daily conditions such as the influence of hot water, steam, rapid changes in temperature and humidity, for many years. That's why we pay attention to every detail in their production..

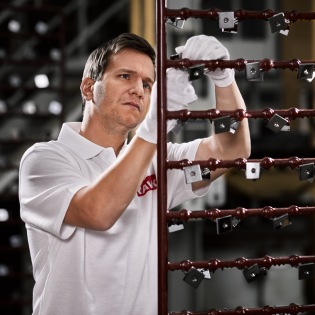

We use high-quality alloyed aluminum for the production of shower frames, which we further surface treat. We carry out all the treatment in our own galvanizing and painting shop. This is absolutely crucial because only in this way do we have 100% control over the preparation of shower frames. We also prevent their damage, which usually occurs during the transport of production material.

We anodize, chrome or paint the frames of shower enclosures. For painting, we use epoxy polyester paints, which are the highest quality of powder paints - they are elastic, chemically resistant and resistant to aging, and at the same time colour stable.

In the galvanizing shop, we also carry out surface treatment of handles, hinges or screen support bars. Thanks to the combination of solid metal and high-quality chrome plating, we can guarantee a very long lifespan for these elements, which has been confirmed by a lifespan test of 30 years.

The frames are then fitted with high-quality glass panels made of safety tempered glass, 6 or 8 mm thick. The glass is also treated with our own patented RAVAK AntiCalc® technology, which acts against the deposition of limescale. This makes cleaning the shower enclosure easier and faster.